Pipeline Inspection Companies | In-Line ILI Inspections

Cathodic Protection Solutions LLC for pipeline inspection companies using a smart pig in-line inspection tool (ILI). With revolutionary technology and practical solutions, we provide comprehensive pipeline services including in-line inspections, assessment and repairs in Midland, Permian Basin and the USA.

According to the requirements of the Pipeline and Hazardous Materials Safety Administration (PHMSA), the inspection reporting deliverables include the Pigging Report, Magnetic Flux Leakage Report (MFL), Electronic Geometry Profile Report (EGP) and a Summary Report.

In-Line Inspections ILI

After the pipeline has been cleaned, the in-line ILI inspection provides Ultrasonic, EGP and MFL inspections in-line with precise Pig Locator functionality. The in-line inspection provides the key metrics for assessing pipeline integrity, improving safety and reducing the required personnel without interrupting pipeline operation. The video visual inspection puts your eyes on the mark and provides analytics from inside the pipeline like never seen before.

View the In-Line Inspection Tool

Dummy MFL Pipeline Cleaning and Preparation

The Dummy MFL uses a magnetic brush spinning in a bi-directional movement to clean and clear metal debris from inside the pipeline wall. As implied by the name, the Dummy MFL tool is a single-section replica of the MFL tool, but without internal and external electronics attached to the tool. The heavy-duty magnetic brush efficiently cleans the internal surface wall of the pipeline in preparation for the in-line inspection.

MFL In-line Inspection Technique

The Magnetic Flux Leakage (MFL) is a non-destructive testing technique that uses electro-magnetic device to detect corrosion and pitting inside the pipeline. The MFL tool uses permanent magnets to magnetize the pipe wall to saturation. We use Hall effect sensors with double the data sampling rate than that of existing tools offered by our competitors. The MFL uses a powerful magnet to magnetize the conductive material on the pipeline walls with a magnetic detector placed between the poles of the magnet where it can detect leakage. Defects, such as corrosion or material loss, leak from the steel pipeline and are captured in graphic form using the MFL tool.

ILI Differential Global Positioning System

Differential Global Positioning System (DGPS) is an enhancement to the Global Positioning System (GPS) to provide improved location accuracy. In the best case implementation, we improved accuracy from 15-meters in nominal GPS down to 10-centimeters. DGPS refers to the use of receivers and satellites to reduce or eliminate the common satellite-to-receiver based errors such as orbit, ionospheric, tropospheric and the clock. In one example using DGPS, we improved the positional accuracy from 1.5-meters with standard GPS, down to 40-centimeters using DGPS.

EGP In-Line Inspection Technique

The Electronic Geometry Profile (EGP) is used to map out the internal geometry of the pipeline. The internal pipeline features and deformations on the pipeline surface are detectable by the EGP survey. Features of the pipeline geometry survey include bends, bend radius and angle of the turn. Cross section deformation, ovalities, dents and wrinkles. Also detectable are girth welds, valves, tees, tie-ins and changes to the internal diameter.

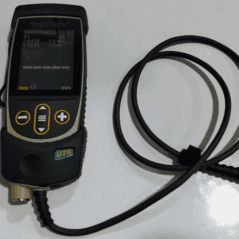

ILI Visual Display | Smart Pig Tracking and Locator

Designed exclusively for smart pigging, the Pig Tracker & Locator uses transmitters and receivers to enable visual display and audible signals for stopped and moving pigs. The “walk and stop” extraneous signal noise is filtered out by the Pig Tracker & Locator resulting in more accurate detection and reporting of pig passage locations with date and time stamps.

All in-line inspection activity is reported on a graphic menu system. The panel display reveals the distinctive pulsing pattern of a passing pig and the precise location of stationary pigs. This information is provided real-time to onsite personnel and in printed reports with distribution to any computer device, mobile or desktop.

In-Line Ultrasonic Testing & Crack Detection

ILI Ultrasonic testing is the non-destructive testing technique that sends ultrasonic waves through an object or material, such as a pipeline. The tool transmits high-frequency sound waves through the pipeline to both characterize the material and detect flaws. The inspection tool requires access to only one side of the pipeline for the inspection and there is no radiation hazard in ultrasonic examination, thus, there is no disruption to pipeline operations. As an added feature, volumetric and other crack defects can be detected irrespective of orientation. Contact us for in-line inspections in Midland, Texas, and globally.

Request a Quote | Schedule In-Line Inspection

Please complete the below form to Request a Quote or Schedule an In-Line Inspection in the USA. We will confirm the technical requirements and schedule date.