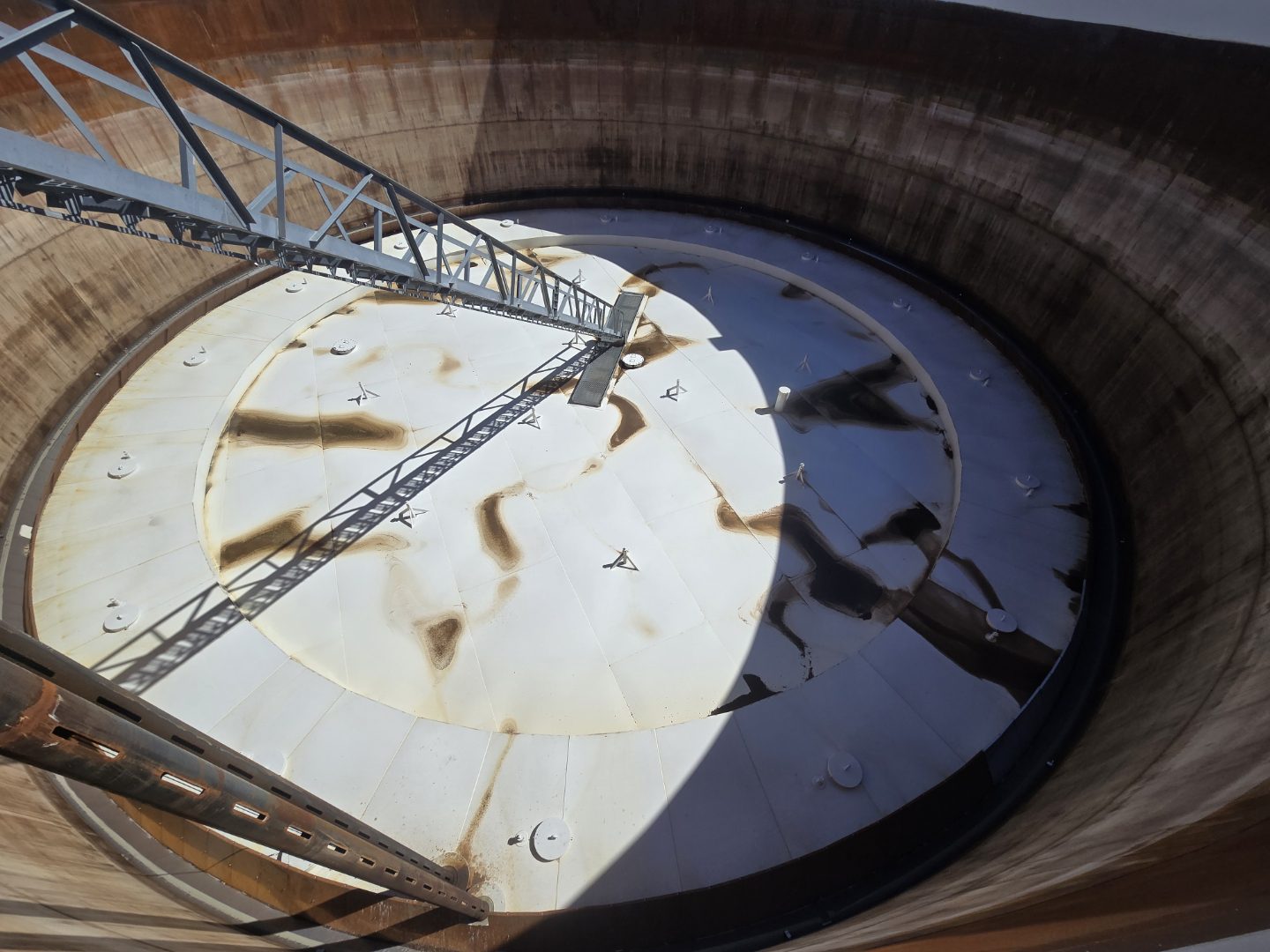

Technical Description of Secondary Seal Inspection on a Floating Roof in a Crude Oil Tank

Purpose:

The secondary seal on a floating roof serves as an additional barrier to minimize vapor loss and prevent external contamination (like rainwater or debris) from entering the stored crude oil. Its inspection ensures the seal’s integrity and functionality, preventing environmental and operational hazards.

Inspection Steps:

- Pre-Inspection Preparation:

- Safety Procedures:

- Ensure compliance with safety protocols, including gas testing for flammable atmospheres and use of proper personal protective equipment (PPE).

- Verify that tank operations (e.g., filling or emptying) are halted to stabilize roof movement during inspection.

- Documentation Review:

- Review tank design, secondary seal specifications, and maintenance history.

- Access Equipment:

- Ensure safe access to the external rim of the floating roof, such as through scaffolding or approved man-lifts.

- Safety Procedures:

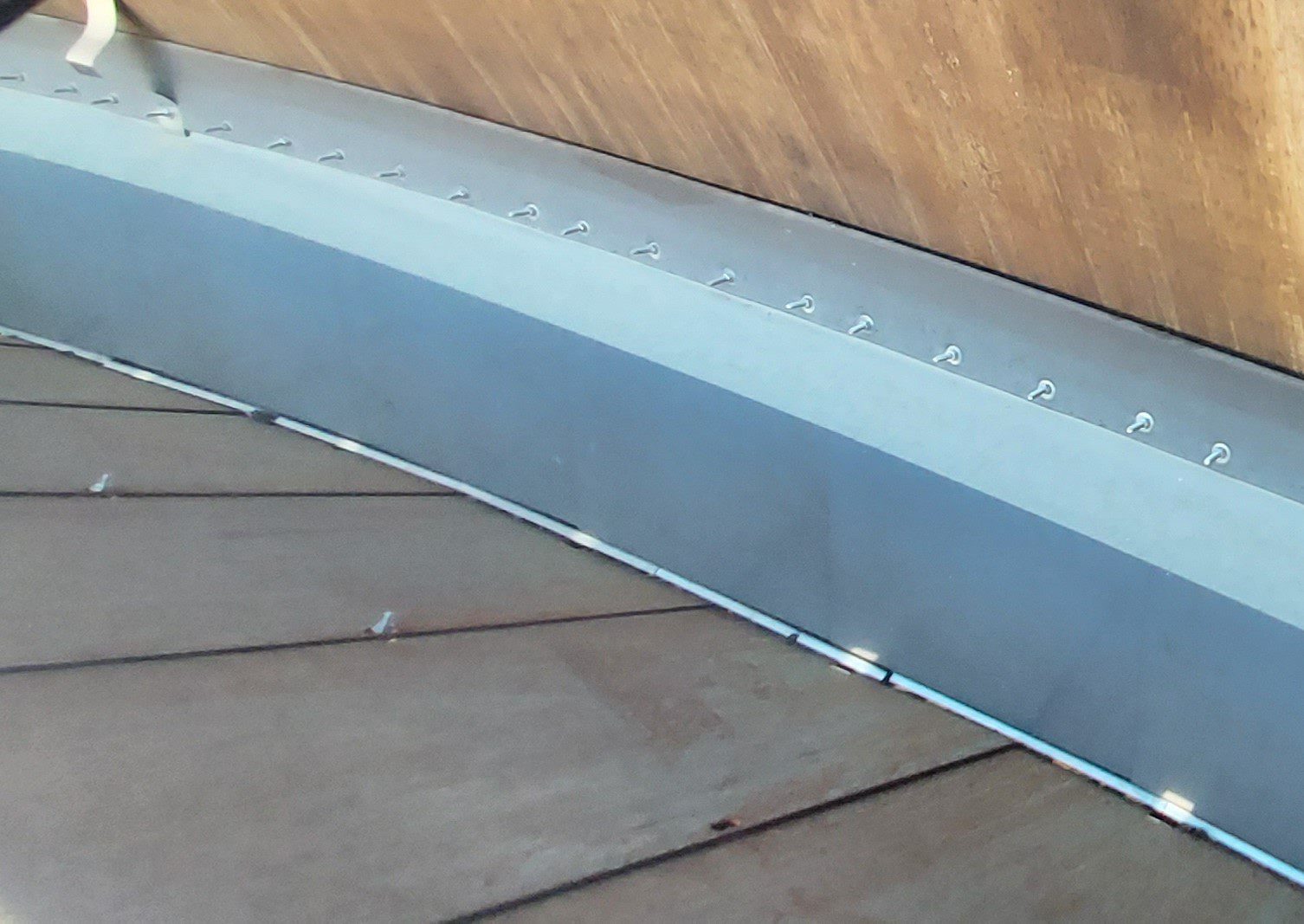

- Visual Inspection:

- Examine the seal-to-tank-shell contact for:

- Gaps or misalignment.

- Tears, cracks, or material degradation in the seal.

- Check for wear or damage on supporting hardware (e.g., clamps, springs, or tensioners).

- Inspect the seal’s flexibility to accommodate tank deformation or roof movement.

- Examine the seal-to-tank-shell contact for:

- Seal Alignment and Coverage:

- Verify that the secondary seal maintains continuous contact with the tank shell across the full circumference.

- Measure and record any gaps between the seal and tank wall to ensure compliance with allowable tolerances, as defined by standards like API 650.

- Structural Integrity:

- Check for corrosion, bending, or damage on:

- Secondary seal’s mounting bracket.

- Rim plate or any structural attachments.

- Ensure that all fasteners are secure.

- Check for corrosion, bending, or damage on:

- Weather Shielding:

- Assess weathering protection components (e.g., rain caps or deflectors) for effectiveness and signs of wear.

- Ensure that no rainwater pathways bypass the seal.

- Vapor Loss and Emission Prevention:

- Check for staining, discoloration, or other indicators of vapor or liquid leaks around the seal area.

- Conduct testing if required (e.g., through gap testing or sniffers for emissions).

- Environmental and Debris Inspection:

- Inspect the roof area for accumulated debris, water, or ice that could compromise the seal.

- Remove any foreign objects impeding seal operation.

Post-Inspection Activities:

- Reporting:

- Document findings, including photographs, measured gaps, and areas of concern.

- Provide recommendations for repairs or adjustments as necessary.

- Repair Planning:

- Schedule maintenance or seal replacement if defects exceed tolerances or threaten tank operation integrity.

- Compliance Verification:

- Ensure inspection aligns with relevant industry standards such as API 650, API 653, and local regulations.

Inspection Frequency:

- Performed routinely during tank maintenance cycles or based on regulatory requirements, typically aligned with scheduled API 653 inspections.

This structured approach ensures the floating roof’s secondary seal functions optimally, protecting both the stored product and the environment.